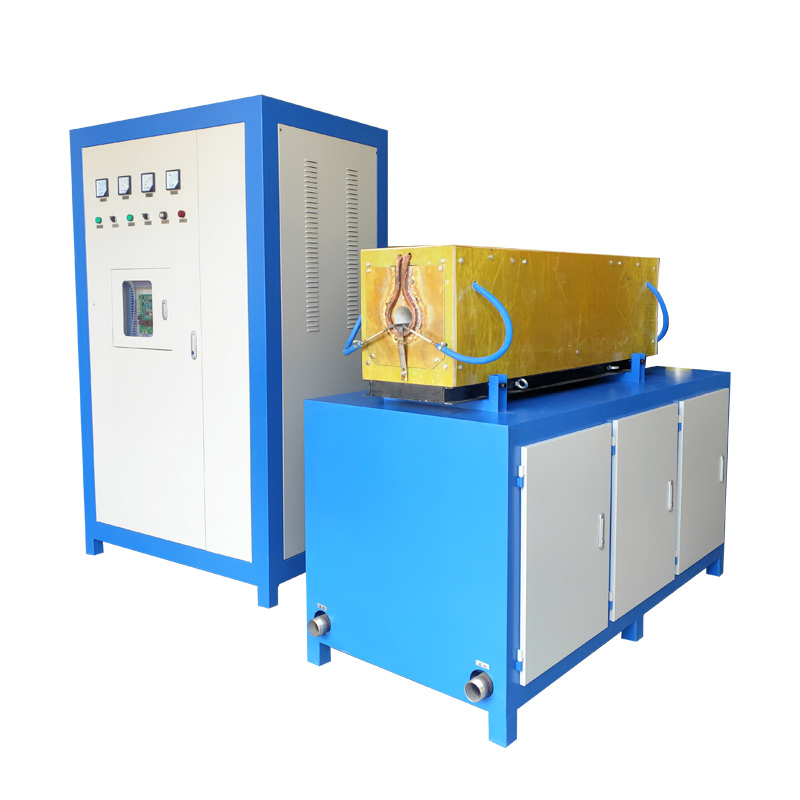

5KG Gold Melting Furnace Working Principle of High Frequency Copper Melting Furnace

After the induction heating equipment outputs a strong alternating frequency current, a strong alternating magnetic field is generated through the induction coil. Under the action of the magnetic field, an eddy current is formed on the surface of the heated workpiece, thereby rapidly heating the workpiece.

Features of induction heating

A. Fast heating: The heating speed is less than 1 second, and the heating speed can be adjusted and controlled.

B. Wide application: It can heat metal workpieces of various types. (Induction coils are made according to the shape of the workpiece)

C. Low power consumption: high thermal efficiency, so it can save energy compared with other heating methods (such as gas, oxygen, acetylene, coking coal, electric furnace, high frequency of electronic tubes, etc.).

D. Good effect: The surface of the workpiece is heated evenly and the temperature rises quickly, which reduces the oxide layer on the surface of the workpiece and the degree of deformation of the workpiece.

E. High efficiency: The equipment has an automatic setting function, and the operation can be completed by one person, thereby reducing the number of processes and improving efficiency.

F. Small footprint: The equipment is small in size, light in weight, and takes up less than half a cube of space, making it easy to move and move.

G. Easy to operate: CNC type design, the whole machine does not need to be debugged, the installation and operation are very convenient, and it can be learned in 5 minutes.

H. Good environmental protection: no noise, pollution and open fire, it is easier to meet the requirements of environmental protection and fire protection.

The use of induction heating equipment

1. Hot forming (hot forging, diathermy forming, hot rolling, hot upsetting)

2. Welding (brazing, thermal fit, thermal fusion)

3. Heat treatment (quenching, annealing, tempering, quenching and tempering)

4. Smelting (various metals such as gold, silver, copper, iron and stainless steel)

Selection principle of induction heating equipment

The power determines the heating speed of the workpiece, and the frequency determines the temperature difference between the inside and outside of the workpiece.

main feature

1. Adopt IGBT solid state inverter technology, high efficiency and energy saving, high output power.

2. Negative performance rate design, can work continuously for 24 hours.

3. Digital phase-locking technology to achieve automatic frequency tracking.

4. Modular design, simple installation, convenient operation, no need to debug.

5. Perfect protection function, high reliability and easy maintenance.

6. The resonant frequency conversion technology is adopted to make the whole machine efficient and efficient.

7. It can replace other heating methods (such as gas, coking coal, oil furnace, electric furnace, high frequency electronic tube, etc.), energy saving and environmental protection.

浙公網安備 33038102331513號

浙公網安備 33038102331513號