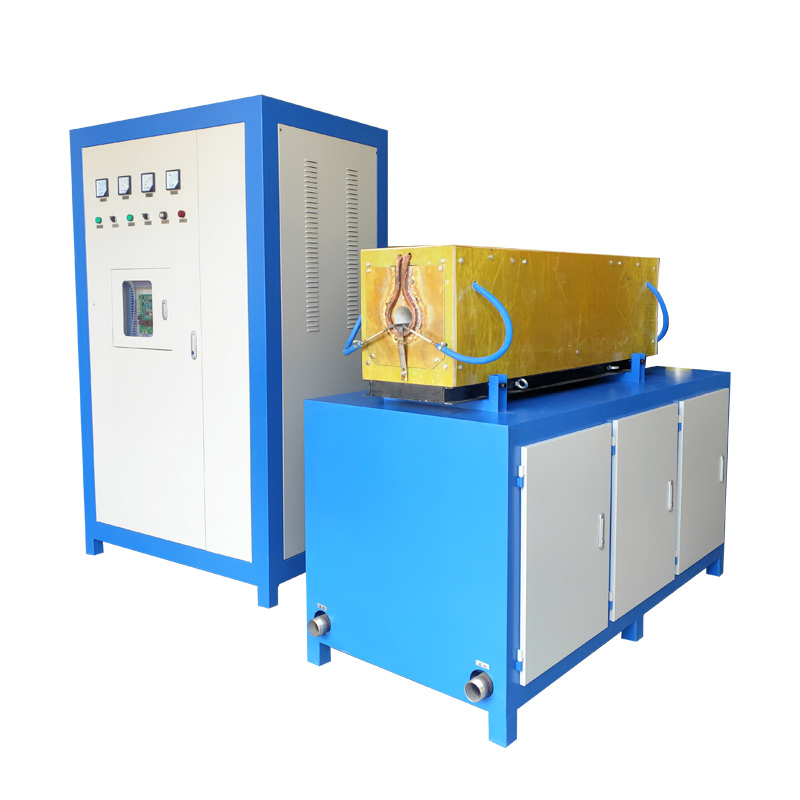

1. The main features of local heating and annealing equipment for steel pipes, steel pipe annealing furnaces, and steel pipe annealing equipment

The medium frequency induction heating equipment produced by Wenzhou Ruiao Technology Co., Ltd. can be used for heating of various round bars, sheets or special-shaped metal materials before forging, extrusion, hot rolling and shearing, as well as the overall quenching and tempering, annealing and tempering of metal materials. Wait for heat treatment.

[1] Fast heating speed and less oxidative decarburization. Since the principle of intermediate frequency induction heating is electromagnetic induction, the heat is generated by the workpiece itself. This heating method has fast heating rate, very little oxidation, high heating efficiency, good process repeatability, and only slight decolorization of the metal surface. The surface restores the specular light height, so as to effectively obtain constant and consistent material properties, especially suitable for various precision forgings.

[2] The degree of automation is high, which can realize fully automatic unmanned operation and improve labor productivity.

[3] Uniform heating and high temperature control accuracy: uniform heating, to ensure that the temperature difference between the heating core and the surface is small. The temperature can be accurately controlled through the temperature control system to ensure product repeatability. The large-scale bar material is continuously fed to reduce the impact on the intermediate frequency power supply, and the temperature closed-loop control composed of the power supply and the participation of the fast feeder will ensure that the heating temperature of the billet is consistent, and the temperature difference between the core surface can be controlled within ±10 degrees.

[4] The induction furnace body is easy to replace: according to the size of the workpiece, different specifications of the induction furnace body need to be configured. Each furnace body is designed with water and electricity quick-change joints, which makes the furnace body replacement simple, fast and convenient

[5] High heating efficiency, compared with other heating methods, it effectively reduces energy consumption, high labor productivity, no pollution, and equipment meets environmental protection requirements.

【6】Complete equipment protection: The whole machine is equipped with water temperature, water pressure, phase loss, overvoltage, overcurrent, voltage limit/current limiter, start overcurrent, constant current and buffer start, so that the equipment starts smoothly and the protection is reliable and fast. run smoothly. Low energy consumption and no pollution

Serve:

1. Implement (1+1) technical after-sales service for users, that is: after a piece of equipment leaves the factory, a full-time engineer will provide perennial technical tracking services.

2. The warranty period is 12 months. Provide lifetime repair and maintenance services.

3. During the warranty period, if the equipment is damaged and the components are damaged due to quality problems during normal use, the seller will repair and replace the damaged parts free of charge. If the user fails to use it improperly, the seller will repair it free of charge and charge the cost of the components.

4. In case of failure, the seller promises to rush to the buyer's site for processing within 48 hours after receiving the buyer's notice.

浙公網安備 33038102331513號

浙公網安備 33038102331513號